Manufacturing Workshop 30,000㎡

Brick Production Lines

Energy Saving

Higher Efficiency

Bricmaker offers full ranges red bricks making equipment: raw materials process equipment (crushing, mixing, conveying and feeding), brick vacuum extruders & cutters, green brick grouping & stacking system, drying & firing kilns, red bricks automatic pallet machine, etc.

We have series of vacuum extruders to meet different capacity requirements from 8,000-60,000 pcs bricks/hour. They are designed with advanced import technologies and the main wear parts are made of superior quality durable materials.

Read More

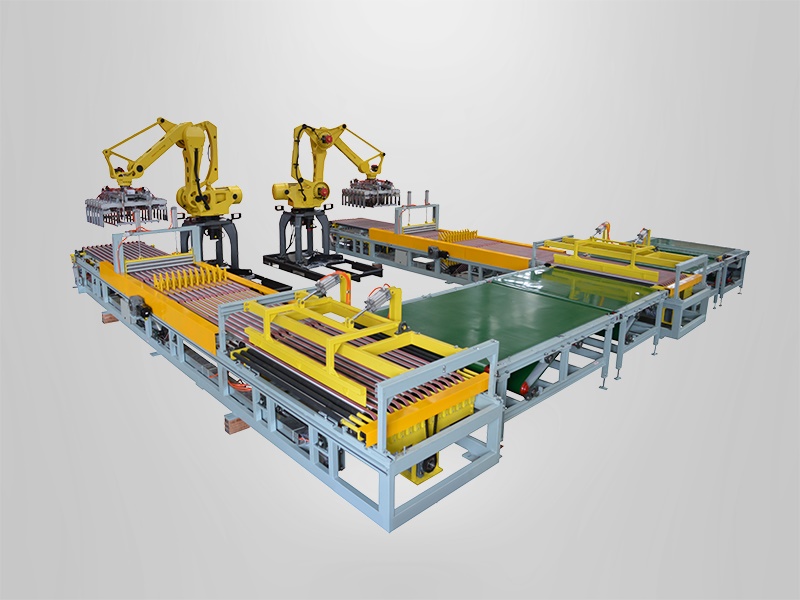

Fully automatic cutting, group and robot system is a most cost-effective investment for modernized brick factories. We have series of models to meet different output, stacking types, brick sizes requirements. It greatly reduces the manual cost, and improves brick quality consistency and efficiency.

Read More

Rotary tunnel kiln, also called movable tunnel kiln, is a most advanced and automatic fire kilns of red bricks. The drying, preheating, firing, cooling processes are distributed on an annular track with diameter of 80-120m. The whole firing processes could by integrated operated by PLC control.

Read MoreWHY CHOOSE US

Test the raw materials’ chemical and physical property determines the feasibility of brick making project.

Realize expected output, smooth flow chart, select suitable process according to actual situation. Pay high attention to raw materials refine treatment, kiln design, and stack method.

Bricmaker offers you reliable, easy operated, cost effective, advanced technology, wide optional equipment and we support your equipment installation and trial production.

Bricmaker provides you advanced management concept and help you improve your efficiency and reduce your production cost.

If you’re looking for reputable supplier who can bring you valued brick making equipment and professional services, please contact with us. We are pleasant to offer you with more information if needed.

We chat