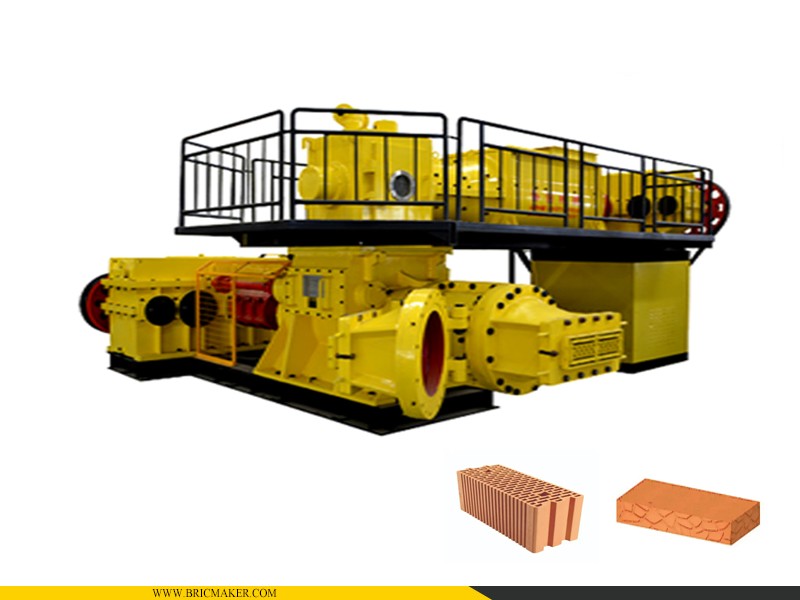

Semi-Auto Clay Brick Production Line Hourly Output 10,000 PCS Green Bricks

- Category: Automatic Clay Brick Production Lines

- Raw materials: Clay, Soil

- Application: making building bricks

- Brick sizes: customized

- Hourly output: 10,000pcs-15,000pcs

Semi-Auto Clay Brick Production Line Hourly Output 10,000 PCS Green Bricks

1. Brief introduction:

This semi-auto clay brick production line is to adapt to small and middle brick factories. The hourly output is 10,000 to 15,000 pcs standard bricks. The raw material is clay soil. The whole brick making processes are: automatic soil feeding-soil fine crushing-soil mixing-vacuum extrusion-automatic cutter-manual unloading green bricks to dryer ground-manual stack and nature air dry-manual transfer the dried bricks to kilns-Manual stack bricks in kilns-fire bricks-unloading fired bricks. The features of this production line are low investment, higher output and lowest changes on original manual production technologies.

2. Main features:

3. Main equipment configuration of the brick plant:

| S/N | Equipment name | Model | Power(kw) | Qty(set) |

| 1 |

Box feeder |

XGD1000 |

7.5+3 | 1 |

| 2 | Magnetic iron remover |

RCYB-6.5 |

/ | 2 |

| 3 | Double roller crusher |

GS80x60 |

30X2X2 | 2 |

| 4 | Double shaft mixer | SJ400X37 | 55 | 1 |

| 5 | Double stage vacuum extruder | JKY55-4.0 | 275 | 1 |

| 6 | Water circling vacuum pump | ZGZB-12000 | 22 | 1 |

| 7 | Air compressor | W-0.9/7 | 7.5 | 1 |

| 8 | Auto program controlled cutter | QTF1+QPF1 | 9 | 1 |

| 9 | Green brick unloading machine | ZB-12 | / | 1 |

4. Main technical parameters of vacuum extruder:

| Date | Units | JKY55/50-4.0 |

| Production capacity | pcs/h | 10,000-15,000 |

| Reamer diameter | mm | 550/500 |

| Maximum extrusion pressure | Mpa | 4.0 |

| Moisture content | % | 14-20 |

| Vacuum degree | Mpa | ≤-0.092 |

| Upstage shaft speed | r.p.m | 30-33 |

| Downstage shaft speed | r.p.m | 22-26 |

| Total power | kw | 185+75+7.5x2 |

| Overall dimension | mm | 6500x320x2050 |

| Total weight | kg | 25000 |

5. Equipment installation & commission:

Bricmaker has been contracting overseas brick factories newly built, old factory reform. We provide brick production technology consult, overall brick factory design, brick production equipment, equipment installation and commissioning, etc.

We will make seaworthy packing for our equipment.

The delivery period: within 45 days after advance payment.

7. To provide you tailor designed solution, kindly let us know details of your requirements as below:

- Are you already running a red brick making factory? Or totally new project?

- What is your raw material to make bricks?

- How many green bricks would you make per hour? And how many red bricks would your kiln fire each day?

- What are your finished brick sizes? Solid or hollow? Any picture or drawing would help.

- What is your brick making technology? One time stack drying and firing? Or stack for drying and re-stack for firing?

- How would you like the automation? Semi-auto or fully auto? We have fully automatic production line for your option.

- Do you need kilns? We also provide equipment for fire kilns.

8. Why choose Bricmaker?

- Bricmaker has over 10 years experiences in exporting Chinese brick making automatic equipment;

- Bricmaker provides you higher automation, most advanced production technology, making you competitive in your market;

- Bricmaker has professional overseas service team and we ensure your brick plant smoothly running;

- We provide one stop services for your brick factory: brick making technology, brick equipment, repair and maintenance.

INQUIRY

CATEGORIES

- Automatic Clay Brick Production Lines

- Rotary Tunnel Kiln

- Tunnel Kilns

- Vacuum Extruder

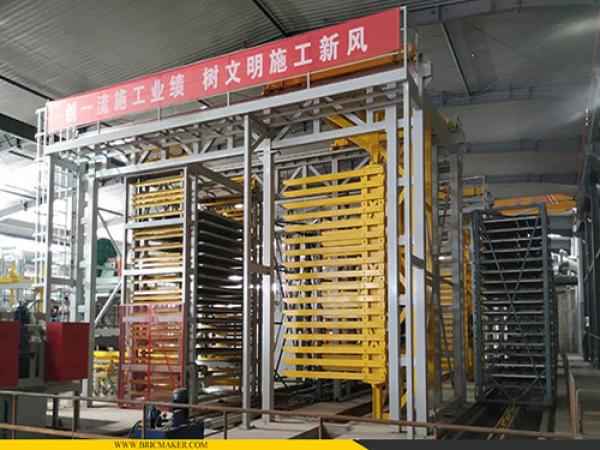

- Green Brick Cutting Group Transfer System

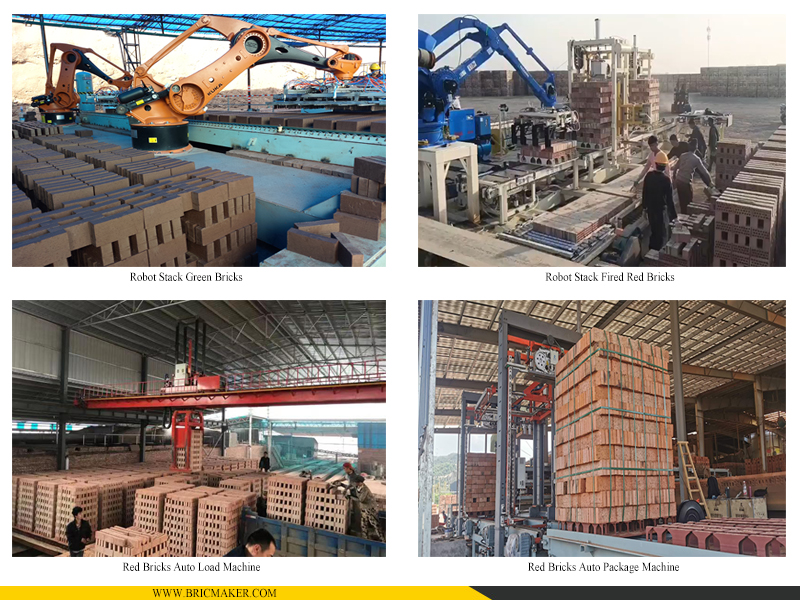

- Brick's Robot Auto Stacking System

- Brick's Raw Material Process Machines

- Aging Warehouse Equipment

- Red bricks load & package machine

- Kilns' Refractory Materials

- Desulfurization tower

CONTACT US

Name: General Manager

Mobile:+8613151630928

Whatsapp:+8613222235952

Email:sales@bricmaker.com

Add:No.1, Huayu Road, Donglai Development Zone, Zhangjiagang City, Jiangsu, China