Email: sales@bricmaker.com Phone: +8613151630928

1. Brief introduction

The SO2 purification tower is widely used for gas purification in the brick and tile industry. It uses alkali as a solvent and can absorb acidic gases such as SO2, So3, HCl etc.

The flue gases from the furnace enter the desulfurization tower tangentially, the fine smoke and dust contained in the flue gases are absorbed and collide with each other to form particles. Under the action of centrifugal force, they are thrown onto the wall of the tower and, under the action of a film of water, are pulled to the bottom of the tower; The exhaust gas swirls up the tower wall and collides at high speed through the rotating layer with the atomized desulfurization liquid. At this time, the three-phase flow of gas, liquid and solid comes into complete contact, and the SO2 in the exhaust gas is mostly absorbed by the alkaline components in the liquid, thereby completely purifying the exhaust gas.The cleaned flue gases are dewatered using demisters and discharged via a flexible chimney.

The residual liquid after desulfurization is drained from the bottom of the tower into the ash washing channel. After sedimentation in the clarifier (with a small amount of dust in the flue gas), the clarified liquid is then sent via a desulfurization pump to the tower body, where it is recycled. A small amount of wastewater is discharged from the desulfurization plant; After a certain period of time, the sludge present in the circulation tank is cleaned manually or mechanically.

2. Main technical parameters

|

Desulfurization efficiency |

≥92%, (pH>9) |

|

Allowable fluctuation range of flue gas volume |

30%~110% |

|

Cylinder resistance |

900~1100Pa |

3. The advantages of Alkali type desulfurizer tower

4. The working principle

The desulfurizer tower uses NaOH solvent to absorb the SO2 in the flue gas, the reaction equation as below:

2NaOH+SO2→Na2SO3+H2O (1)

Na2SO3+H2O+SO2→2NaHSO3 (2)

Notes:

a. Equation (1) represents the main reaction of SO2 absorption by the desulfurization solution during the start-up stage, when the NaOH solution absorbs SO2 and the pH value of the regeneration solution is high (above 8);

b. Equation (2) represents the main reaction when the pH value of the desulfurization solution is low (5-8).

c. As the absorption process going, the amount of Na2SO3 in the absorption solution increases, and the absorption capacity of the absorption solution decreases. It is necessary to add alkaline solution to the absorption solution, maintain a relatively stable concentration ratio of Na2SO3 in the absorption solution, and regularly discharge a portion of the waste liquid.

d. The acidic gases such as SO3 and HCl contained in the flue gas will also be absorbed by the absorbent.

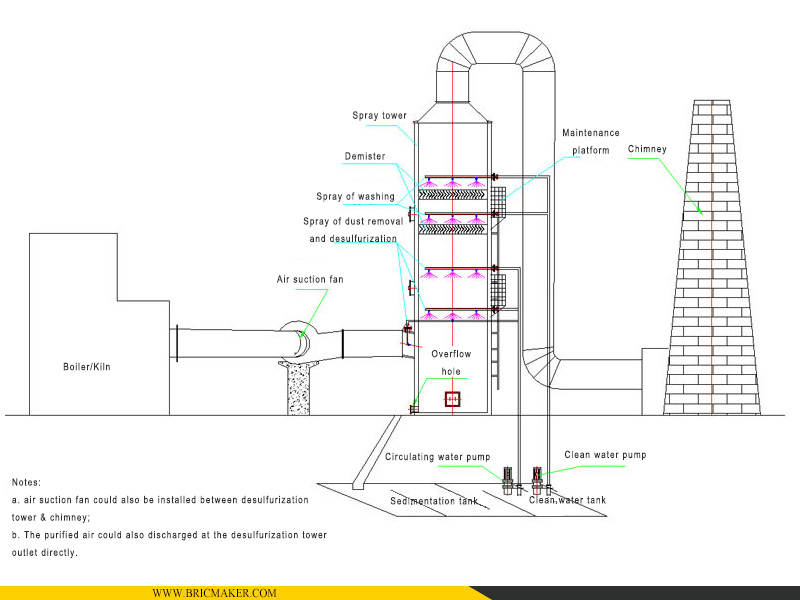

5. The structure diagram of desulfurizer tower

The SO2 absorption system consists of a desulfurization tower, an internal spray system, a cyclone, a mist separator, an absorption liquid circulation pump, a pipeline power supply and other components.

6. Detail images:

Name: General Manager

Mobile:+8613151630928

Whatsapp:+8613222235952

Email:sales@bricmaker.com

Add:No.1, Huayu Road, Donglai Development Zone, Zhangjiagang City, Jiangsu, China

en

en We chat