Chào mừng: Suzhou Bricmaker Automation Co.,Ltd

1. Brief introduction

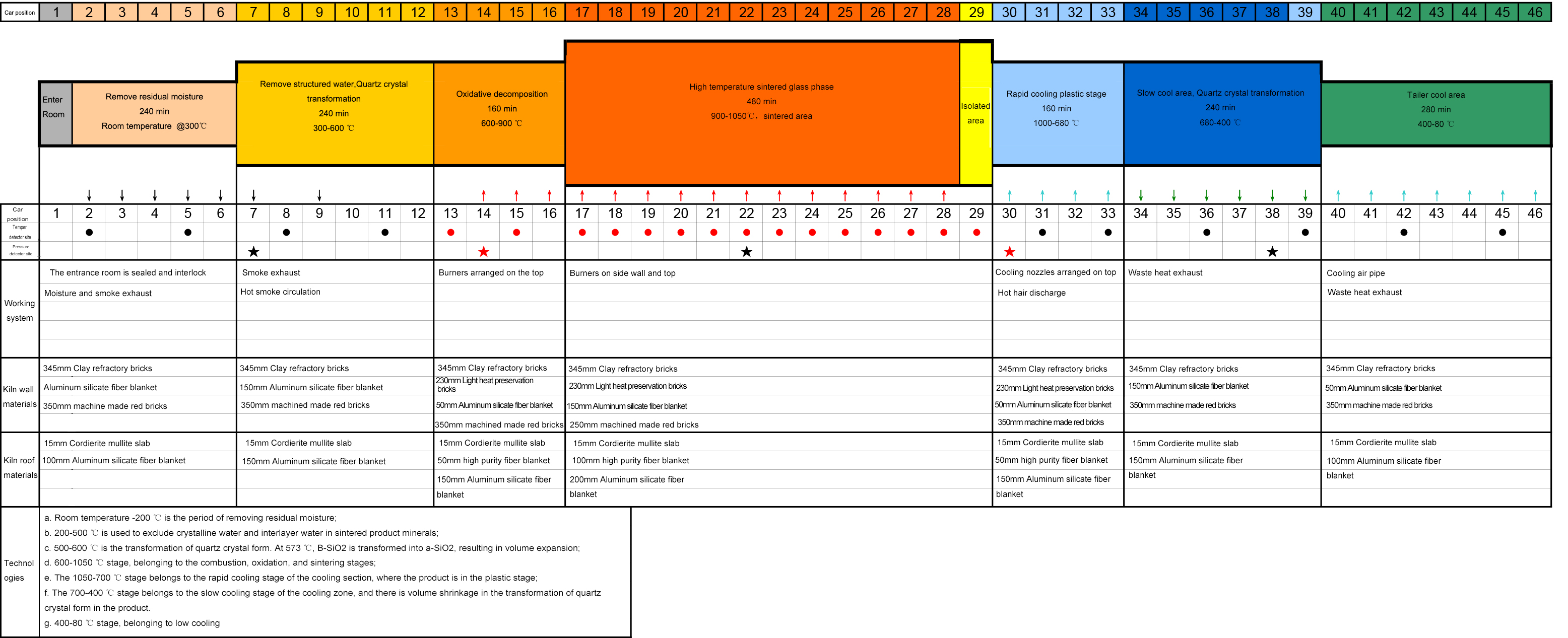

Clay brick tunnel kiln is the most popular thermal kiln for baking building bricks because of its characteristics of continuous operation, stable thermal performance, high efficiency and stable quality. Compared to the traditional external tunnel oven, this oven has a larger cross-section and a shorter cooking cycle. clay brick tunnel kiln consists of kiln body, kiln car and conveyor equipment, combustion system, air exhaust system, control system, etc.

It adopts heavy oil as fuel to baking the bricks. The burning system adopts circulation return pipeline arrangement. The heavy oil is heated before supplied to each group of burners. The whole burning system is managed by computer system.

2. Main technical parameters:

|

No. |

Function & Item |

Unit |

Parameter & Index |

Remarks |

|

1 |

Type of kiln |

|

Flat roof type tunnel kiln |

|

|

2 |

Product type |

|

Clay block |

Hollow type |

|

3 |

Daily capacity (single line) |

pcs |

≥70,000 |

400x200x200mm |

|

4 |

Length of kiln |

m |

162.8 |

|

|

5 |

Width inside of kiln |

mm |

8600 |

|

|

6 |

Size of kiln cart |

mm |

3600x8600 (LxW) |

|

|

7 |

Capacity of kiln cart |

set |

45 (inside of kiln) |

Total 68 |

|

8 |

Loading capacity of each kiln cart |

pcs |

2160 |

Approx22 tons |

|

9 |

Valid height of loading |

mm |

2050 |

Designing 10 layers |

|

10 |

Block moisture before entering kiln |

% |

3~5 |

|

|

11 |

Firing temperature |

℃ |

950-1050 |

Designing 1150℃ |

|

12 |

Fuel type |

|

Heavy oil |

Thermal value: approx. 9500~10000 kcal/kg |

|

13 |

Cycling of firing |

H |

24-40 adjustable |

Designing 31.5H |

|

14 |

Qualification rate of firing |

% |

≥98 |

|

|

15 |

Energy consumption per unit |

kca/kg |

≤350 |

|

|

16 |

Way of stacking & firing |

|

2-time stacking & burning process, Automatically loading & unloading |

|

|

17 |

Way of smoke evacuation |

|

Mechanical smoke evacuation |

|

|

18 |

Control method |

|

PLC/PID automatic intelligent instrument control system, IPC Management |

|

Tên: General Manager

Di động:+8613151630928

WhatsApp:+8613222235952

E-mail:sales@bricmaker.com

Thêm vào:No.1, Huayu Road, Donglai Development Zone, Zhangjiagang City, Jiangsu, China

We chat